enn energy committees to supporting safety and stable green energy to operation regions. as safety is the cornerstone of enn energy’s business, we emphasised the safety motto "risks must be visible, major risks identified and well managed" and "safety must become enn's brand". practically, we carry out safety management in all scenarios, continuously increase investment and inspection of safety management, optimise the safety management system, and use digital security management to consolidate the foundation of corporate security operation.

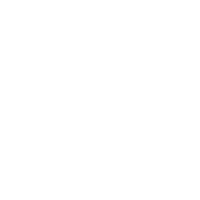

the safety production committee of the company is lead by ceo, and responsible for supervising executions of health and safety-related works. we have also formed a three-level occupational health and safety organisation system through the company’s headquarters, departments, teams, guaranteeing the safety operation of enn energy.

the three-level occupational health and safety organisation system

our safety management targets

regulations for safety management

regulations for the red and yellow lines of safety management

regulations of enn energy holdings limited for reporting, investigation and disposal of accidents

management measures for emergency plans of production safety accidents

safety management document no. 1

enn energy regulations for safety management

work requirements on the covid-19 prevention and control

important notice on employees’ return to work after the spring festival holiday

notice on daily office work during the period for covid-19 prevention

management regulations for suppliers’ construction safety management

enn energy holdings limited supplier health, safety and environment (hse) policy

under the trend energy structure transition to clean and low-carbon energy, natural gas security and supply maintaining are the top priorities. to consolidate the foundation for safe operation and ensure intrinsic safety, enn energy has taken multiple measures in different scenarios to continuously strengthen the level of intrinsic safety management.

safety supply to back up livelihood

the safety and stability of the gas supply is the primary task of enn energy's social responsibility. we are committed to providing safe and stable green energy for the region, and regard safety as the cornerstone. accordingly, we requested member companies to access quality management system in accordance with iso 9001. in view of the key work of ensuring the safety and stability of the gas source during the winter season, enn energy has set up a winter protection team before winter to analyse the supply and demand situation of in winter, formulate the winter gas supply plan, and ensure the stable operation of winter gas supply.

meanwhile, big data are applied to set up intelligent demands and price prediction model algorithms, which can calculate the most optimal gas resources allocation solutions. the company has formulated emergency plans and carries emergency drills to enhance the emergency response awareness and ability of all employee, in response to emergencies such as extreme weather and safety accidents.

employees from enn lu’an conducted emergency plans and drills at diffawareness erent sites to enhance the emergency response and ability of all employees.

members from enn zhejiang inspected safety protection facilities under attack by typhoon to strengthen the city’s gas consumption safety.

the company’s self-development intelligent inspection vehicles can accurately identify gas leakage, and visualise the potential risks, record inspection data, and automatically upload inspection reports to the management platform.

iot equipment to support functions such as real-time monitoring and alarming to guarantee stability and safety of gas supply

unifying risks identification and rectification standards, operator system and forms of application form, developing the intelligent safety inspection system 2.0, and publishing the “indoor safety risks inspection analysis” signboard and benchmark, thus improving the operation capability of intelligent operation.

the “safety map” application integrates key safety risk indicators such as hazards dynamic, facility and equipment status, contractor situation, and dangerous operations, etc., uniformly analyses the safety level of member companies, and displays the daily safety management key points.

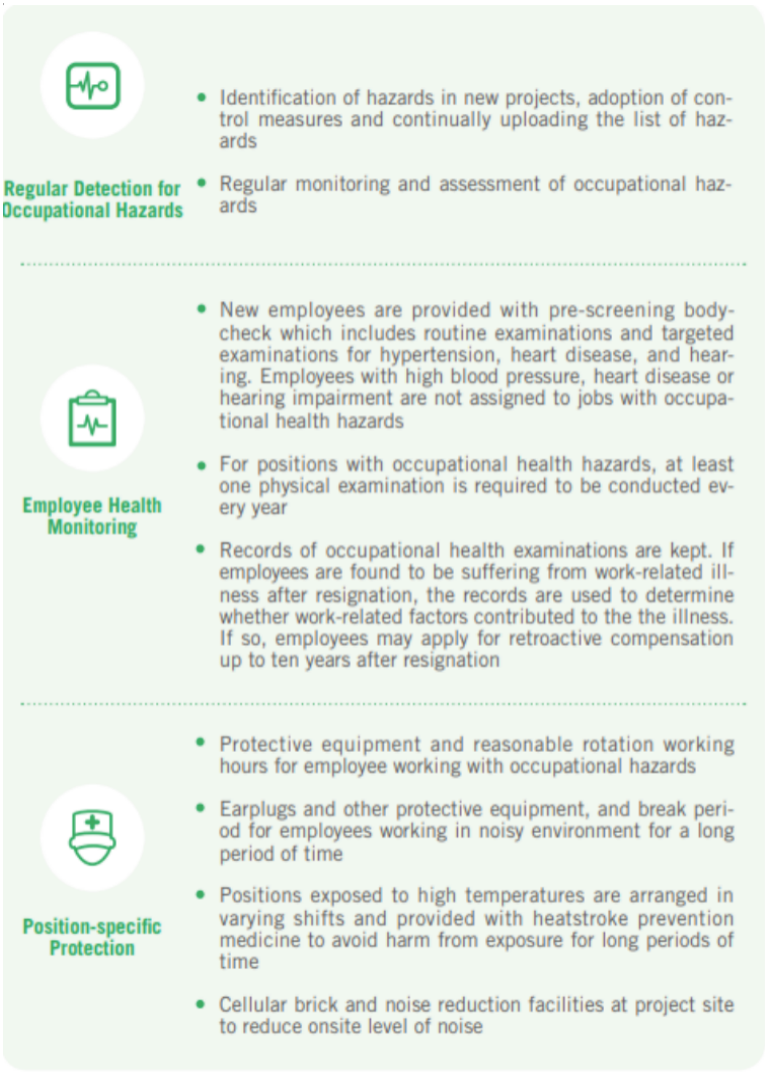

enn adheres to the concept of “employees are the most precious wealth of the company”. it pays close attention to health and safety-related issues of employees and has formulated related policies and taken action to develop the occupational health and safety management. it also learns from international management system and promotes occupational health and safety culture to fully protect the health and safety of employees.

occupational health and safety protection

in addition to stronger administrative management, enn energy also emphasises health and safety management skill education, self-protection and safety redline awareness. we regularly organize employees to participate in safety knowledge learning, safety knowledge competitions, safety knowledge sharing and other activities to cultivate safety management capabilities, and develop targeted safety training courses for employees in special positions with occupational hazard factors, and strive to strengthen their awareness of safety risks.

health and safety of contractors is one of the important management factors in enn energy's safety management system. we intend to promote the construction of occupational health and safety in the supply chain and drive the progress of safety awareness in the industrial chain. in order to better manage the occupational health and safety of contractors, we have issued systems such as the "supplier hse policy" and the "supplier corporate social responsibility code of conduct" to incorporate important esg concern indicators such as contractors health and safety into the contractors access, evaluation and elimination process.

contractor health and safety management initiatives |

1. relevant certification are required for key positions |

2. contractors are required to complete initial and refresher safety production training and pass the assessment before the start of construction |

3. contractors are required to use their own personal protective equipment (ppe) that meet job requirements, and to prepare and register the ppe regularly |

4. suppliers are encouraged to identify and mitigate various hazards and risks in the production process by installing cameras and conducting in-depth, on-site management and inspection for high-risk operations |

5. the accountability system is automated, so that in the event of violations, such violations will be traced back to the relevant personnel and linked to their performance |

6. setting safety accident control targets for contractors and require suppliers to report safety incidents to the headquarters in a timely manner and to handle them properly |